Respirator Training

Why It Matters and How to Do It Right

Respirators play a vital role in protecting workers from harmful dust, fumes, vapors, and airborne contaminants. But simply handing out respirators isn’t enough — without proper training, even the best gear can fail. That’s where respirator training comes in.

Whether you’re managing a construction site, a healthcare setting, or an industrial facility, OSHA regulations require employers to ensure their workers are not only equipped with appropriate respirators but also trained to use them safely and effectively.

Let’s break down why respirator training is critical, what it should include, and how to get your team up to speed — with the help of a practical video guide.

Why Respirator Training Is Non-Negotiable

Respirators are often the last line of defense in a hazardous environment. But they’re only as effective as the person wearing them. Without training, workers might:

- Choose the wrong type of respirator for the hazard

- Wear it incorrectly or inconsistently

- Fail to recognize when a respirator is damaged or compromised

- Forget to perform a seal check

- Misunderstand cleaning or maintenance requirements

According to OSHA, inadequate training is a common violation. And more importantly, it puts lives at risk.

What Does Proper Respirator Training Include?

A well-rounded respirator training program should cover the following essentials:

1. Types of Respirators and Their Uses

There are several types of respirators, including:

- N95 filtering facepieces (common in healthcare)

- Half-face and full-face elastomeric respirators

- Powered air-purifying respirators (PAPRs)

- Self-contained breathing apparatus (SCBA)

Each has specific uses and limitations. Training should include how to identify and choose the right one.

2. Fit Testing

Fit testing ensures the respirator forms a proper seal on the wearer’s face. OSHA mandates annual fit testing for tight-fitting respirators. Workers should also be trained to perform a user seal check every time they put it on.

3. Proper Donning and Doffing

Wearing a respirator the wrong way defeats its purpose. Training must include:

- How to put the respirator on (donning)

- How to take it off safely (doffing)

- How to avoid contamination during the process

4. Maintenance and Storage

Reusable respirators need to be:

- Cleaned regularly

- Inspected for damage

- Stored in a clean, dry location

Neglecting this can shorten the life of the respirator or reduce its effectiveness.

5. Recognizing Signs of Respirator Failure

Training should help workers recognize when a respirator:

- No longer seals properly

- Has a damaged valve or strap

- Is hard to breathe through, signaling a clogged filter

Video Guide: Hands-On Respirator Training

To make training more effective and accessible, visual learning is key. That’s why we recommend watching the following video:

This video covers the essentials in a clear, step-by-step format, including:

- Types of respirators

- How to put them on and take them off

- Safety checks

- Maintenance tips

It’s a valuable resource to include in your employee onboarding or annual training refreshers.

Safety Tips Every Worker Should Know

Here are a few quick respirator safety reminders to reinforce training:

✅ Always inspect your respirator before and after each use

✅ Never share respirators unless they’re disinfected between uses

✅ Store respirators in sealed, clean bags away from sunlight and chemicals

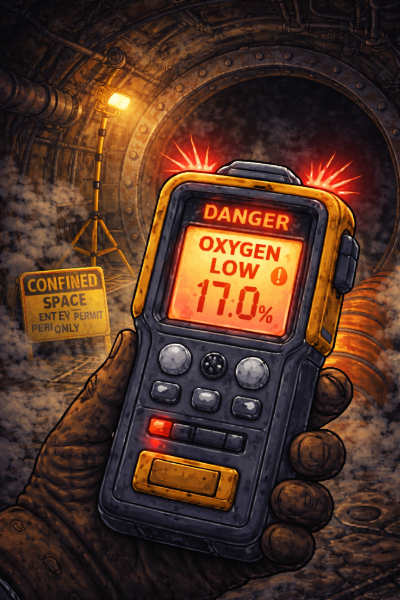

✅ If you feel dizzy, short of breath, or smell contaminants while wearing one — exit the area immediately

✅ Keep facial hair trimmed or shaved to maintain a proper seal (when required)

Why Training Isn’t a One-and-Done

Workplaces evolve — new hazards appear, equipment gets updated, and staff turnover is constant. That’s why respirator training should be ongoing.

Schedule:

- Annual refreshers

- Additional training when new hazards or equipment are introduced

- Follow-up sessions after near-miss incidents

Make sure to document every training session, including attendance, content covered, and date.

Final Thoughts

Respirator training isn’t just a compliance checkbox — it’s a life-saving investment. When workers understand how to properly select, wear, and care for their respirators, they stay safe and productive.

Combine clear policies with hands-on learning tools like the video above, and you’ll foster a safety-first culture that protects your most valuable asset: your people.