Proper Respirator Fitting: Your First Line of Defense in Workplace Safety

In a hazardous work environments, nothing is more crucial than the right personal protective equipment (PPE). And among PPE, the respirator stands out as a critical tool for protecting workers from airborne dangers like dust, fumes, chemicals, and infectious particles.

But simply wearing a respirator isn’t enough — proper respirator fitting is the first and most essential step in ensuring real protection.

Improperly fitted respirators can give a false sense of security, leading to serious health risks.

In this guide, we’ll explore the importance of respirator fitting, how to use one correctly, real-world examples, its historical context, and much more.

What Is Proper Respirator Fitting?

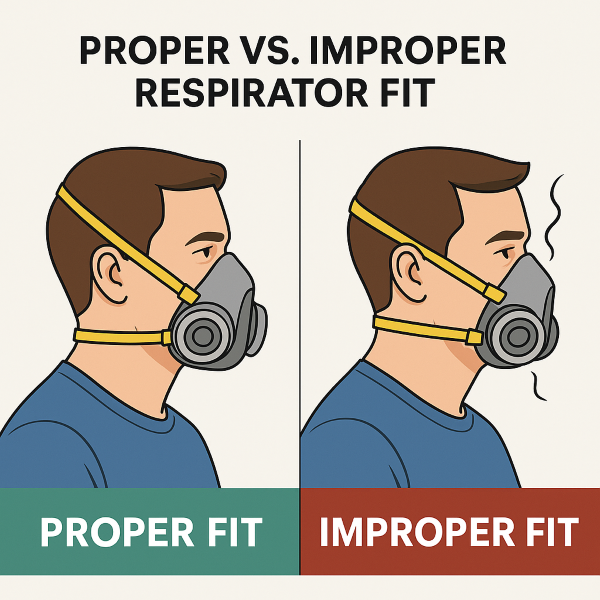

Proper respirator fitting refers to the process of ensuring that a respirator creates a secure, airtight seal on the user’s face. If a respirator doesn’t fit properly, contaminated air can leak in, rendering the device ineffective.

There are two types of fit testing:

- Qualitative Fit Testing (QLFT): A pass/fail method using a test agent (like saccharin or Bitrex) that relies on the user’s sensory response.

- Quantitative Fit Testing (QNFT): Uses a machine to measure leakage into the respirator, providing numerical results for accuracy.

This testing is required under OSHA standards (Occupational Safety and Health Administration) for tight-fitting respirators.

Why It Matters: The Dangers of Poor Fit

Even the best respirator can fail if it’s not fitted correctly. Common risks include:

- Inhalation of toxic or harmful substances

- Long-term respiratory damage

- Exposure to airborne pathogens

- Non-compliance with workplace safety regulations

Proper fitting ensures maximum protection, improves comfort, and encourages compliance among workers.

How to Use a Respirator Correctly

Using a respirator correctly involves more than just putting it on. Here’s a step-by-step overview:

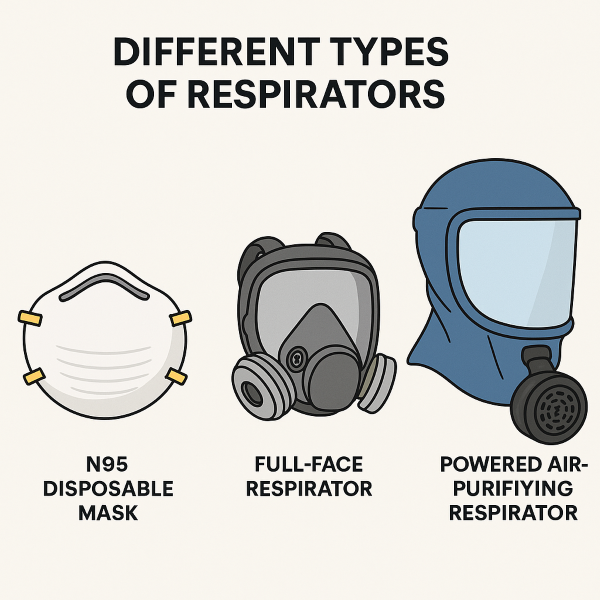

1. Choose the Right Type

- N95, N99, P100: For filtering particulates.

- Half-face or Full-face Elastomeric Respirators: For reusable protection against dust and chemicals.

- PAPR (Powered Air-Purifying Respirator): For higher protection and easier breathing.

2. Perform a Fit Test

- Required annually or when facial features change (weight fluctuation, surgery, facial hair).

3. Check the Seal

- Perform a user seal check every time you wear it.

- Positive pressure test: Exhale gently to detect leaks.

- Negative pressure test: Inhale sharply to confirm suction seal.

4. Maintain and Store Properly

- Clean reusable respirators regularly.

- Store in a clean, dry area away from contaminants.

Real-World Examples of Respirator Fitting Failures

Case 1: Chemical Plant Incident

A worker exposed to airborne solvents suffered respiratory issues due to an improperly fitted half-face respirator. Post-incident investigation revealed the user had facial hair that compromised the seal.

Case 2: Healthcare Setting During a Pandemic

Nurses using N95 masks during the COVID-19 pandemic showed inconsistent protection levels. Those without proper fit testing were more likely to contract the virus.

Case 3: Construction Worker with Dust Allergies

A construction worker using a dust mask instead of a fitted respirator developed asthma-like symptoms. After a proper fit test and switch to an N95, symptoms subsided.

A Brief History of Respirator Use and Fit Testing

Respirators have evolved from simple cloth masks to advanced filtration systems. Here’s a timeline:

- 1910s: Cloth masks used in mining and industrial jobs.

- 1940s: Gas masks popularized during WWII for chemical warfare.

- 1970s: OSHA established mandatory respirator standards.

- 1980s–Present: Introduction of fit testing protocols and NIOSH certification.

Today, OSHA (Standard 1910.134) mandates fit testing, training, and medical evaluations for all respirator users in workplaces with respiratory hazards.

Comparison Table: Popular Respirator Types and Fit Testing Requirements

| Respirator Type | Best For | Fit Testing Needed | Reusable | Notes |

|---|---|---|---|---|

| N95 Disposable Mask | Dust, pathogens | Yes | No | Most common in healthcare settings |

| Half-Face Elastomeric | Chemicals, dust | Yes | Yes | Replaceable filters |

| Full-Face Respirator | High-exposure environments | Yes | Yes | Protects eyes and face too |

| PAPR | Chemical, medical settings | Sometimes | Yes | Ideal for high-risk, long-duration use |

| Surgical Mask (Not a respirator) | General hygiene | No | No | Not designed to seal |

FAQs About Respirator Fitting

Q1: How often should fit testing be done?

A: Annually, or whenever there’s a significant facial change.

Q2: Can you wear a respirator with a beard?

A: Not recommended. Facial hair interferes with the seal. OSHA advises against it.

Q3: Is a surgical mask a respirator?

A: No. Surgical masks are not designed to seal the face and don’t require fit testing.

Q4: What happens if I skip the fit test?

A: You risk inadequate protection and may violate workplace safety regulations.

Q5: How do I know if my respirator fits properly?

A: Perform a user seal check every time you put it on. If you feel air leaking, it likely doesn’t fit.

Summary: Why Proper Respirator Fit Is Your Best Protection

A respirator is only as effective as its fit. Whether you’re in healthcare, construction, manufacturing, or emergency response, ensuring a tight, tested fit could mean the difference between health and harm. From OSHA compliance to real-world protection, taking fit seriously protects both workers and employers.

Takeaway: If you use a respirator, get fit tested regularly, follow usage protocols, and never assume one-size-fits-all.

Final Thoughts

Your first line of defense in hazardous environments is not just the equipment, but how you wear it. Investing in proper fit testing, training, and compliance not only protects your health but also builds a safer workplace culture. Don’t take chances — make respirator fitting a non-negotiable part of your safety protocol.