Oxygen Deficiency Hazards and How to Detect Them

Why Oxygen Deficiency Is So Dangerous

Oxygen deficiency is one of the most serious air hazards found in confined spaces. Unlike many contaminants, low oxygen levels cannot be seen, smelled, or felt until the body is already under stress.

Normal air contains about 20.9 percent oxygen. When levels drop below safe limits, the body is affected quickly. Even small reductions can impair judgment and coordination. Severe drops can lead to unconsciousness or death within minutes.

Because there is little warning, oxygen-deficient environments are a leading cause of confined space fatalities.

For a broader overview of why confined spaces change air safety rules, see Confined Space Air Safety: Hazards, Monitoring, and Worker Protection.

How Oxygen Is Displaced in Confined Spaces

Oxygen deficiency occurs when oxygen is removed or displaced by other gases.

Common causes include:

- Nitrogen, argon, or carbon dioxide displacing oxygen

- Fuel combustion or welding consuming oxygen

- Rusting or corrosion in tanks and vessels

- Fermentation or biological processes

- Chemical reactions during cleaning or maintenance

These processes may occur slowly or rapidly. In confined spaces, even gradual oxygen loss can reach dangerous levels without being noticed.

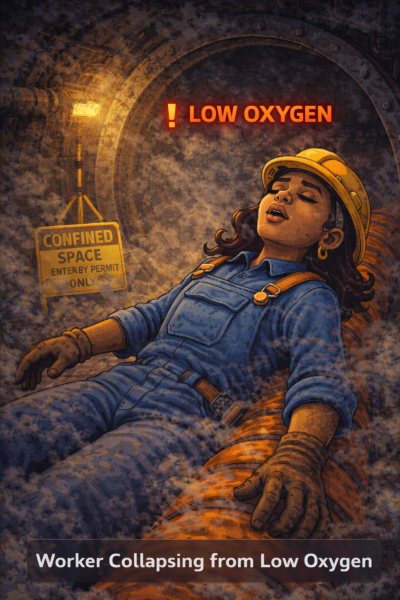

Why Oxygen Loss Is Silent and Deadly

Unlike toxic gases that may irritate the eyes or lungs, oxygen deficiency often produces no early warning signs.

As oxygen levels fall, workers may experience:

- Lightheadedness or dizziness

- Confusion or poor decision-making

- Loss of coordination

- Sudden collapse

At very low levels, a worker may lose consciousness without realizing anything is wrong. Rescue attempts often fail when others enter the same environment without understanding the hazard.

This is why relying on physical symptoms is extremely dangerous.

Why Respirators Often Fail in Low-Oxygen Environments

A common misconception is that wearing a respirator makes entry safe.

Most air-purifying respirators do not supply oxygen. They only filter contaminants from the surrounding air. If there is not enough oxygen to breathe, filtering the air does nothing to protect the worker.

Even supplied-air systems have limits that must be clearly understood before entry.

Understanding what respirators can and cannot do is covered in Types of Respirators and When to Use Them.

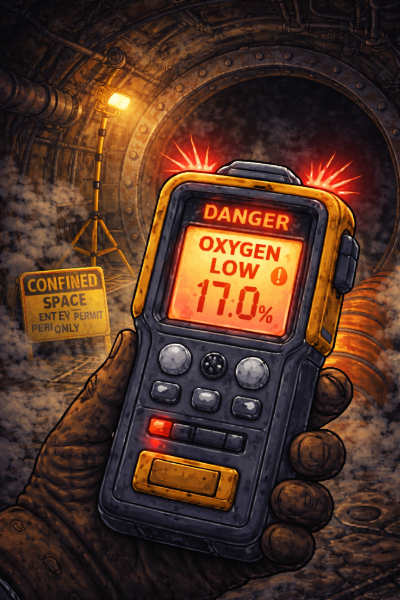

How Oxygen Deficiency Is Detected

Because oxygen loss provides little warning, detection must occur before and during entry.

Oxygen sensors and gas monitors measure oxygen concentration in real time and alert workers when levels fall outside safe ranges.

Monitoring allows teams to:

- Determine whether entry is allowed

- Identify changing conditions during work

- Exit immediately if levels become unsafe

An overview of how these devices function and why they are critical is explained in Gas Monitors and Air Detection Devices.

Pre-Entry and Continuous Monitoring

Oxygen levels should never be assumed safe based on previous entries.

Best practice includes:

- Testing air before entry

- Monitoring continuously while work is performed

- Setting alarms that provide immediate warnings

Confined spaces can change quickly due to equipment operation, leaks, or chemical reactions. Continuous monitoring provides the only reliable warning.

Monitoring requirements and best practices are discussed further in Confined Space Gas Monitoring Requirements and Best Practices.

When Oxygen Levels Make Entry Unsafe

Some oxygen-deficient environments cannot be made safe for entry.

Examples include:

- Oxygen levels below respirator-safe thresholds

- Conditions that change faster than ventilation can correct

- Unknown or uncontrolled sources of displacement

In these cases, the correct response is to stop entry and reassess the task. Adding more PPE does not correct an oxygen-deficient atmosphere.

Recommended Products

Portable 4-Gas Monitor with Pump and Oxygen Sensor

This portable 4-gas detector is designed to measure oxygen levels and common confined space hazards including carbon monoxide (CO), combustible gases (EX/LEL), and hydrogen sulfide (H₂S). It features a built-in pump for drawing air into the sensors, allowing pre-entry testing and continuous monitoring during work. The LCD display shows real-time readings, and audible, visual, and vibration alarms alert workers to unsafe conditions.

A rechargeable battery and included calibration kit help maintain reliable performance when the device is properly maintained. This type of monitor helps determine whether oxygen is within safe ranges and whether other gases are present before and during confined space entry. It supports informed decisions but does not replace proper ventilation, permits, or trained supervision.