Asbestos Gloves in Industrial Work

Why They’re Dangerous and Safer Alternatives

Safety notice: Always follow OSHA, NIOSH, and workplace safety requirements when selecting personal protective equipment (PPE).

In extreme heat environments such as foundries, welding shops, and metal fabrication plants, hand protection is critical. Historically, asbestos gloves were used because of their ability to withstand intense heat. Today, however, asbestos gloves are widely recognized as hazardous and are no longer considered acceptable PPE.

This guide explains:

- Why asbestos gloves were historically used

- Why they are now considered dangerous

- Which modern heat-resistant gloves meet today’s industrial safety standards

For a broader overview of modern hand protection materials, ratings, and use cases, see our Ultimate Guide to Anti-Cut Gloves.

Why Asbestos Gloves Were Used (Historical Context)

Asbestos gloves were manufactured using woven asbestos fibers, a material once valued for its exceptional heat resistance and durability. Decades ago, they were commonly used in industries such as:

- Foundries

- Welding operations

- Glass manufacturing

- Chemical processing facilities

Historical Heat Resistance

Asbestos gloves could withstand temperatures approaching 1,500°F (815°C), which made them attractive for high-heat tasks before safer materials were available.

Why Asbestos Gloves Are Dangerous

Asbestos is a known carcinogen. When asbestos fibers become airborne due to wear, aging, or damage, they can be inhaled and lodge in the lungs.

Health risks associated with asbestos exposure include:

- Mesothelioma

- Asbestosis

- Lung cancer and other respiratory diseases

Because of these risks:

- New asbestos PPE is restricted or banned in many countries

- OSHA and NIOSH discourage any continued use

- Employers are expected to replace asbestos PPE with safer alternatives

Many modern gloves combine heat resistance with cut protection and improved dexterity. These materials and ratings are explained in our Ultimate Guide to Anti-Cut Gloves.

Asbestos Gloves vs. Modern Heat-Resistant Gloves

| Feature | Asbestos Gloves (Legacy) | Modern Heat-Resistant Gloves |

|---|---|---|

| Heat Resistance | Up to ~1,500°F | 900°F–2,000°F (material dependent) |

| Health Risk | High | Low to none |

| Dexterity | Low | Medium to high |

| Regulatory Status | Restricted / phased out | OSHA & NIOSH compliant |

| Recommended Today | ❌ No | ✅ Yes |

Modern materials now provide equal or better thermal protection without exposing workers to severe health hazards.

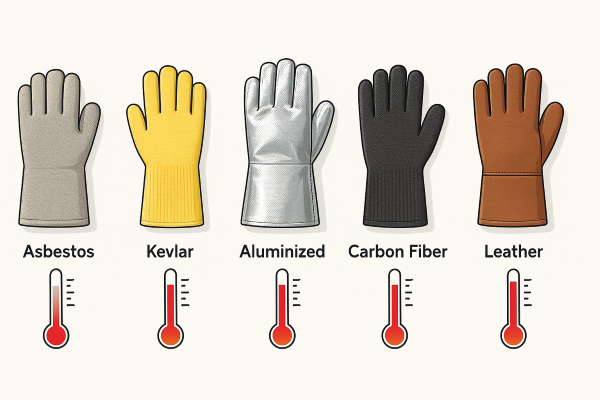

Modern Safer Alternatives to Asbestos Gloves

Today’s high-heat gloves are engineered to protect against extreme temperatures while maintaining dexterity and regulatory compliance.

Kevlar® Gloves

- Moderate heat and cut resistance

- Lightweight with good dexterity

- Common in welding and industrial maintenance

Aluminized Gloves

- Designed for extreme radiant heat

- Ideal for foundries and molten metal handling

- Reflect heat instead of absorbing it

Carbon Fiber & Advanced Composite Gloves

- High heat tolerance

- Resistant to chemicals and abrasion

- Used in aerospace and high-risk industrial environments

Heat-Resistant Glove Material Comparison

| Material | Max Heat Tolerance | Flexibility | Typical Use |

|---|---|---|---|

| Kevlar® | ~900°F | High | Welding, electrical |

| Aluminized | ~2,000°F (radiant) | Medium | Foundries |

| Carbon Fiber | ~1,800°F | Medium | Engineering |

| Treated Leather | ~500°F | High | General industrial |

Are Asbestos Gloves Still Legal?

In many regions, including the United States:

- Manufacturing new asbestos gloves is prohibited

- Existing products are discouraged and often phased out

- Continued use may violate employer duty of care obligations

Always follow:

- OSHA 1910.138 (Hand Protection)

- NIOSH PPE guidance

- ASTM thermal performance standards

If asbestos gloves are present in a workplace, they should be removed and replaced immediately.

How to Choose the Right High-Heat Gloves Today

When selecting modern heat-resistant gloves:

Inspect gloves regularly for wear or damage

Identify the heat type: contact, radiant, or convective

Verify the glove’s temperature rating

Ensure compliance with OSHA and NIOSH standards

Prioritize fit, dexterity, and grip

Final Verdict: Are Asbestos Gloves Worth Using?

No.

While asbestos gloves played a historical role in industrial safety, they are no longer considered safe or acceptable PPE. Modern heat-resistant gloves provide equal or superior protection without exposing workers to serious health risks.

To compare modern glove materials, protection levels, and use cases across industries, refer to our Ultimate Guide to Anti-Cut Gloves.

Upgrading PPE is not just safer. It is required.

TL;DR

- Asbestos gloves are dangerous and outdated

- Modern heat-resistant gloves outperform asbestos without health risks

- OSHA-compliant alternatives should always be used

- Replace any legacy asbestos PPE immediately