Common Confined Space Entry Mistakes That Lead to Injury or Death

Why Confined Space Incidents Keep Happening

Many confined space injuries and fatalities occur during routine tasks. Workers may believe the job is familiar, the space is small, or the risk is manageable.

The reality is that confined spaces are unforgiving. Small mistakes escalate quickly, especially when air conditions change without warning.

Understanding the most common failure patterns helps prevent repeating them.

For the full framework on confined space air safety, see Confined Space Air Safety: Hazards, Monitoring, and Worker Protection.

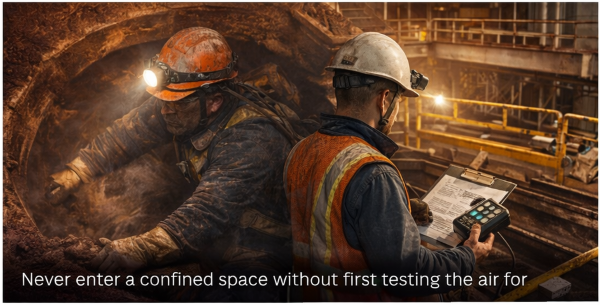

Mistake 1: Assuming the Air Is Safe Because It Was Safe Before

One of the most dangerous assumptions is believing that a space is safe because it was safe during a previous entry.

Air conditions can change due to:

- New work activities

- Equipment operation

- Chemical reactions

- Environmental changes

Testing must occur before every entry, regardless of past experience.

Failing to reassess air conditions is a leading cause of confined space incidents.

Mistake 2: Overreliance on Respirators

Respirators are often viewed as a solution rather than a control with limits.

Common errors include:

- Using air-purifying respirators in oxygen-deficient spaces

- Assuming higher protection levels make any entry safe

- Ignoring respirator limitations

Respirators do not measure air quality and do not replace ventilation or monitoring.

Understanding when respirators are appropriate is covered in Types of Respirators and When to Use Them.

Mistake 3: Ignoring or Disabling Gas Monitor Alarms

Gas monitor alarms exist to provide immediate warnings. Treating them as nuisances rather than alerts can be fatal.

Mistakes include:

- Assuming alarms are false

- Silencing alarms without investigation

- Continuing work after an alarm triggers

Alarms signal that conditions are unsafe or approaching unsafe levels. Ignoring them removes the only early warning workers may have.

Monitoring principles and alarm importance are explained in Gas Monitors and Air Detection Devices.

Mistake 4: Testing Only Before Entry

Air testing is not a one-time task.

Conditions can change rapidly due to:

- Leaks

- Equipment startup

- Chemical use

- Ventilation failures

Testing only before entry creates a false sense of security. Continuous monitoring provides real-time information and allows workers to exit before conditions become dangerous.

Monitoring requirements and best practices are discussed in Confined Space Gas Monitoring Requirements and Best Practices.

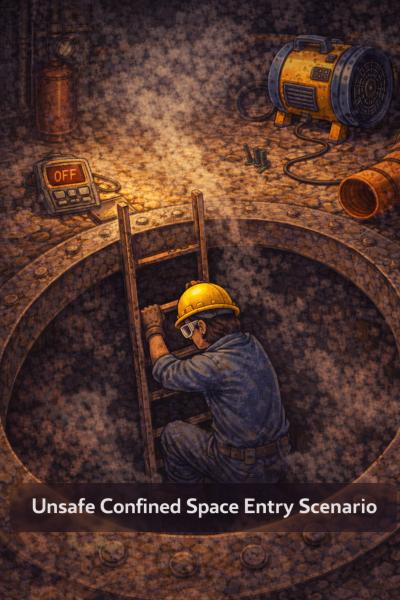

Mistake 5: Poor Ventilation Planning

Ventilation that is poorly planned can be ineffective or even dangerous.

Common issues include:

- Inadequate airflow

- Venting contaminants toward workers

- Failing to verify effectiveness

Ventilation must be planned, monitored, and adjusted based on real air conditions.

The role of airflow control is covered in Ventilation and Airflow Control in Confined Spaces.

Mistake 6: Inadequate Fit Testing and Training

Even when respirators are appropriate, they must fit properly to work as intended.

Mistakes include:

- Using unfit-tested respirators

- Improper donning or seal checks

- Lack of worker training

Poor fit reduces protection and increases exposure risk.

The importance of fit testing is explained in Respirator Fit Testing.

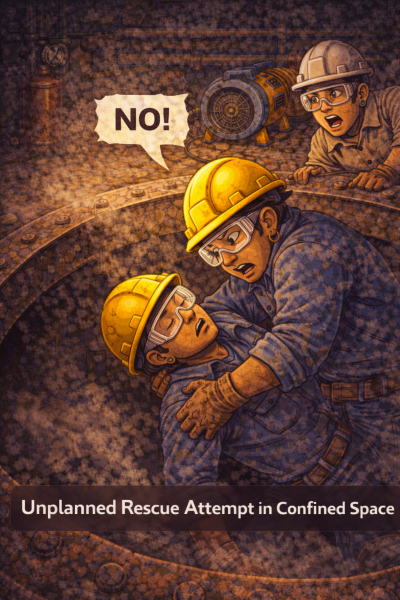

Mistake 7: Unsafe Rescue Attempts

Some of the deadliest confined space incidents involve would-be rescuers.

Common scenarios include:

- Coworkers entering without protection

- No monitoring during rescue

- Lack of ventilation or planning

Rescue without proper controls often results in multiple victims.

Confined space rescue must be planned, not improvised.

How to Break the Pattern

Preventing confined space incidents starts with recognizing that these environments demand different decisions.

Key principles include:

- Never assume air is safe

- Monitor before and during entry

- Ventilate to control hazards

- Understand respirator limits

- Stop entry when conditions cannot be controlled

Confined space safety is not about bravery or speed. It is about judgment.

Equipment That Supports Confined Space Safety Decisions

The following equipment examples are commonly used to support confined space safety practices discussed above. They do not prevent mistakes on their own and must be used as part of a complete confined space program that includes training, monitoring, ventilation, and clear stop-work authority.

Confined Space Warning Signage

Clear warning signage helps identify confined spaces and reinforces that special precautions are required before entry. Proper labeling reduces the risk of workers assuming a space is safe based on familiarity or routine use.

Signage supports awareness but does not replace air testing, permits, or training.

Gas Monitoring Equipment

Gas monitors provide early warning when air conditions become unsafe. When alarms are ignored or disabled, one of the most critical safety controls is lost.

Proper use includes pre-entry testing, continuous monitoring, and immediate response to alarms.

Ventilation Equipment

Ventilation equipment helps control air hazards by diluting or removing contaminants. Poorly planned or unverified ventilation can worsen conditions instead of improving them.

Ventilation effectiveness must always be confirmed through air monitoring.

Optional site-wide disclaimer (highly recommended)

Equipment examples are provided for informational purposes only and do not replace confined space hazard assessments, entry procedures, or training requirements.