Emergency Eye Wash Station: What You Need to Know to Stay Safe

When you’re working in environments where chemicals, dust, or flying debris are common, safety should always be your top priority. In these scenarios, emergency eye wash stations aren’t just recommended—they’re essential.

A moment of exposure to a harmful substance can lead to serious injury or even permanent vision loss. That’s why having a reliable eye wash station within arm’s reach can mean the difference between a quick recovery and a life-altering accident.

Whether you’re outfitting a lab, a manufacturing floor, or a garage workshop, understanding how these systems work—and which one is right for your setting—can protect your employees, yourself, and your workplace from preventable harm.

Why Emergency Eye Wash Stations Are Critical

Accidents involving the eyes can happen in seconds, and the first 10 to 15 seconds after exposure are the most crucial. Substances like acids, alkalis, solvents, or even fine dust can rapidly damage the sensitive tissues of the eye.

An emergency eye wash station allows you to:

- Flush contaminants quickly

- Minimize long-term damage

- Reduce the severity of injuries

- Comply with OSHA and ANSI safety regulations

In short, these stations provide immediate first aid until professional medical treatment can be administered.

Types of Eye Wash Stations

There are several types of eye wash stations on the market, each suited to specific environments. Here’s a breakdown:

1. Plumbed Eye Wash Stations

These are connected directly to your building’s water supply and provide a continuous flow of water.

- Pros: Unlimited water source, ideal for high-risk areas

- Cons: Fixed installation, requires plumbing

2. Portable Eye Wash Stations

These units contain a self-contained tank or reservoir of saline solution or water.

- Pros: Great for remote sites or mobile workspaces

- Cons: Limited capacity, needs refilling

3. Gravity-Fed Eye Wash Stations

Using gravity to dispense water, these are a type of portable station but offer hands-free operation.

- Pros: Easy to mount, reliable flow

- Cons: Limited flushing time

4. Personal Eye Wash Bottles

Compact bottles used as an immediate response before reaching a full station.

- Pros: Extremely portable, fast access

- Cons: Not a substitute for a full 15-minute flush

Top 4 Emergency Eye Wash Stations (Comparison Table)

| Product | Type | Flow Time | Capacity | Best For |

|---|---|---|---|---|

| Honeywell Fendall Porta Stream II | Gravity-fed | 15 minutes | 16 gallons | Remote work areas |

| Speakman SE-580 | Portable pressurized | 15 minutes | 9 gallons | Laboratories, healthcare |

| Guardian G1540 | Gravity-fed | 15 minutes | 16 gallons | General industry |

| PhysiciansCare Eyewash Bottle Pack | Personal bottle | ~1 min | 16 oz | Quick first response |

Where to Use Emergency Eye Wash Stations

Knowing where to install your eye wash station is just as important as having one. According to ANSI Z358.1 guidelines, eye wash stations should be:

- Located within 10 seconds walking distance from the hazard

- Clearly marked and unobstructed

- Able to provide a continuous 15-minute flush at a controlled temperature (60–100°F)

Common installation sites include:

- Laboratories

- Factories and warehouses

- Automotive repair shops

- Chemical processing plants

- Woodshops and metalworking stations

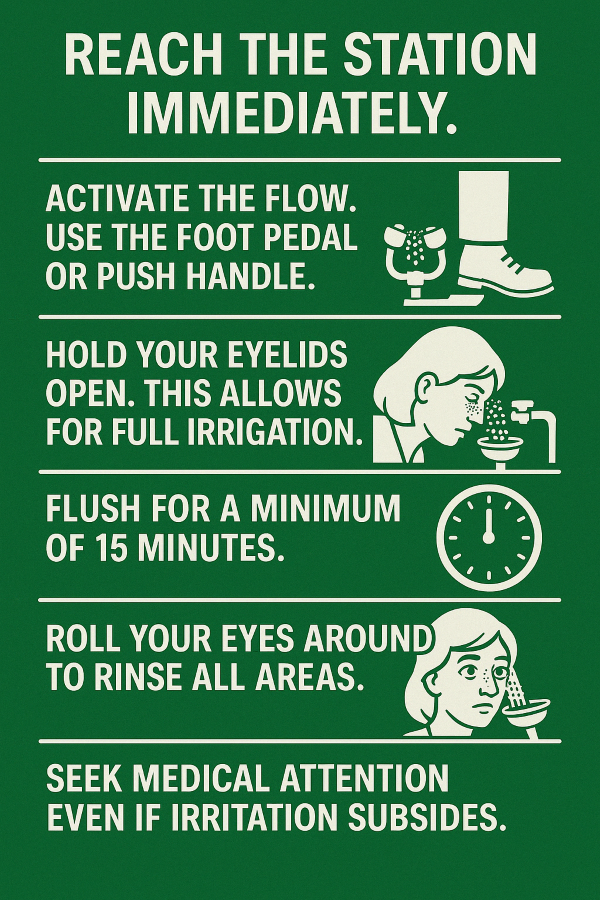

How to Use an Eye Wash Station

In the event of exposure:

- Reach the station immediately.

- Activate the flow. Use the foot pedal or push handle.

- Hold your eyelids open. This allows for full irrigation.

- Flush for a minimum of 15 minutes.

- Roll your eyes around to rinse all areas.

- Seek medical attention even if irritation subsides.

Pro tip: Remove contact lenses as soon as possible during the flush.

Maintenance & Safety Tips

Like any emergency equipment, your eye wash station is only useful if it’s functioning properly. Here’s how to keep it ready for action:

- Inspect weekly for leaks, obstructions, or expired fluid.

- Flush plumbed systems weekly to prevent bacteria buildup.

- Replace saline solution in portable units as per manufacturer guidelines.

- Train staff regularly on location and usage procedures.

- Post clear signage and lighting for visibility.

OSHA and ANSI require that all stations meet compliance standards, so periodic audits are essential.

Choosing the Right Station for Your Workplace

When selecting an eye wash solution, consider the following:

- Risk Level: How likely is exposure in your workspace?

- Mobility Needs: Will the station need to be moved?

- Water Source Availability: Can you connect to a plumbed line?

- Space Constraints: Is there room for a wall-mounted system?

- Maintenance Capabilities: Can your team manage weekly checks?

If your workplace includes high-risk chemicals, a plumbed station may be your best option. On the other hand, for remote job sites or small workshops, a portable or gravity-fed unit offers flexibility without compromising safety.

Final Thoughts: Don’t Wait for an Emergency

Emergency eye wash stations aren’t a “nice-to-have”—they’re a must-have in any environment where eye hazards are present. Fast access to clean, flowing water is a critical component of workplace safety and compliance.

Protect your team, reduce liability, and create a safer work environment by installing and maintaining a properly rated eye wash station. Remember, it only takes one accident to understand why these devices are so important.