The Ultimate Guide to Anti-Cut Gloves: Protection Levels, Types, and Uses

🧤Protection, Types, and the Best Picks for 2026

Why Anti-Cut Gloves Are a Must-Have in 2026

Ever nick your hand while slicing vegetables or catch a sharp edge during a DIY project? It happens fast. One second you’re focused, the next you’re looking for a bandage. That’s where anti-cut gloves, also called cut-resistant gloves, earn their keep.

Anti-cut gloves are designed to reduce the risk of hand injuries when working with knives, metal, glass, or sharp tools. They’re used in kitchens, workshops, construction sites, factories, and at home. The right pair can be the difference between finishing the job safely and losing work time to an avoidable injury.

This guide serves as our central resource on anti-cut gloves. For specialized use cases, we also cover stainless steel chain gloves for extreme cut hazards, woodworking safety gloves for carpentry tasks, and industrial hand protection for high-risk environments.

In this guide, you’ll learn:

- What anti-cut gloves are and how they work

- The different materials and cut protection levels

- The best anti-cut gloves for common tasks in 2026

- How to choose the right glove for your job

- Answers to common questions about cut resistance

Let’s get into it—your fingers will thank you.

🛡️ Section 1: What Are Anti-Cut Gloves?

What Makes a Glove “Cut-Resistant”?

Anti-cut gloves are a type of personal protective equipment designed to resist cuts, slashes, and abrasions from sharp objects. They don’t make your hands invincible, but they significantly reduce injury risk by slowing or deflecting blades and sharp edges.

They are commonly used in:

Manufacturing and industrial work

Food preparation and meat processing

Woodworking and construction

Sheet metal and glass handling

Cut-Resistant vs. Puncture-Proof (The Safety Critical Gap)

Important Safety Note: A common mistake is assuming that “cut-resistant” means “puncture-proof.” It is vital to understand the difference to avoid serious injury.

- Cut Resistance: Protects against “sliding” blades, such as a knife edge or a sheet of glass moving across the fabric.

- Puncture Resistance: Protects against “pointed” objects, such as medical needles, nails, or splinters.

Standard HPPE or Kevlar knit gloves offer very little protection against vertical punctures. If you are working in waste management or medical environments where needles are a risk, you must look for gloves specifically rated under the ANSI/ISEA 105-2016 puncture scale, which often includes specialized “super-fabric” or epoxy-plate palm liners.

How Do Anti-Cut Gloves Work?

Cut-resistant gloves work through material strength and fiber structure. High-performance fibers absorb and distribute the force of a blade instead of allowing it to slice straight through.

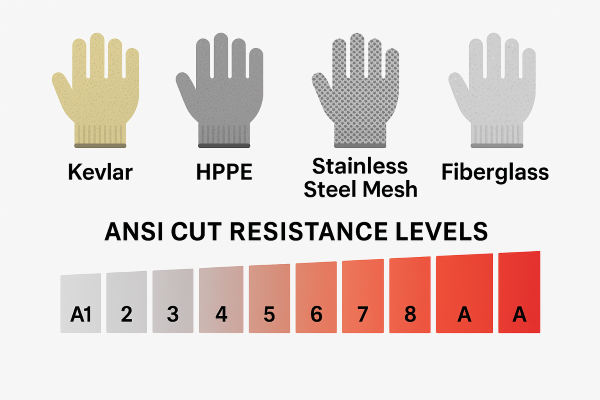

Common materials include:

- Kevlar® – Heat resistant and durable

- HPPE (High-Performance Polyethylene) – Lightweight and flexible

- Stainless steel mesh – Maximum cut resistance

- Fiberglass blends – Added abrasion resistance

- Protective coatings – Improve grip and control in wet or oily conditions

Safety Standards: ANSI vs. EN 388

| Standard | Scale | Meaning |

|---|---|---|

| ANSI/ISEA 105 | A1 (light) – A9 (extreme) | North American standard |

| EN 388 | A (light) – F (extreme) | European equivalent for cut level |

These ratings help you pick the right glove depending on the job’s hazard level.

The “New Pentagon” Label

In late 2024, a new standard (ANSI/ISEA 105-2024) was released. It introduces a Pentagon-shaped label that puts Cut, Abrasion, and Puncture levels into one icon. By 2026, look for the “new unified pentagon label” on glove cuffs.

🧬 Section 2: Types of Anti-Cut Gloves

A. By Material

Kevlar

Heat resistant and durable. Commonly used for mechanical, industrial, and moderate heat applications where both toughness and cut protection are needed. For high-heat environments and legacy industrial PPE considerations, see our guide to asbestos gloves in industrial work.

HPPE (High-Performance Polyethylene)

Lightweight, breathable, and flexible. Ideal for kitchens, warehouses, woodworking, and home projects where dexterity matters. We cover top options in our woodworking safety gloves guide.

Stainless Steel Mesh

Provides extreme cut protection. Commonly used in meat processing, butchering, and environments with high cut risk. For a deeper breakdown, see our guide to SS chain gloves for maximum cut protection.

Fiberglass Blends

Offer strong cut and abrasion resistance. Often used in construction, material handling, and industrial environments.

Nitrile-Coated Gloves

Designed for better grip in oily or wet conditions. Common in automotive, plumbing, and maintenance work.

Polyurethane-Coated Gloves

Lightweight with excellent tactile sensitivity. Best for precision tasks such as electronics and fine assembly work.

B. By Cut Protection Level (ANSI)

- A1–A2: Light tasks and food prep

- A3–A5: General maintenance and woodworking

- A6–A9: High-risk environments like glass or sheet metal handling

C. By Application

- Kitchen: Food-safe HPPE gloves (A3–A5)

- Industrial: Kevlar or steel mesh gloves (A6–A9)

- DIY & Home: Flexible HPPE gloves (A2–A5)

- Electrical or Tactical: Gloves with layered protection and task-specific features

Pro tip: More protection usually means less flexibility. Choose the lowest cut rating that safely handles your task.

Sustainability in PPE (The 2026 Trend)

As we move into 2026, the PPE industry is shifting toward “Green Protection.” When selecting your next pair, look for these emerging features:

CO2-Neutral Manufacturing: Look for brands that highlight carbon-neutral production processes, which are becoming the standard for industrial safety contracts in 2026.

Recycled Yarn: Many manufacturers are now using rPET (recycled polyester) or recycled HPPE to reduce the carbon footprint of hand protection.

Biodegradable Coatings: New nitrile and latex coatings are designed to break down in landfill conditions within a few years, rather than decades.

🔥 Section 3: The Best Anti-Cut Gloves for Every Job (2026 Edition)

For Kitchen and Food Prep

- NoCry Premium (A5, HPPE) – Good balance of safety and dexterity

- Dowellife Stainless Steel Mesh (A9) – Best for heavy cutting and butchering

For Industrial Work

- Schwer ProGuard PR3326 (A9) – Sheet metal and machine shop use

- DEX FIT Cru553 (A5) – Precision work with solid protection

For DIY and Home Projects

- FORTEM HPPE Gloves (A5) – Gardening and general projects

- MaxiFlex 34-874 (A3) – Light repairs and hobby work

Key takeaway: Extreme cut resistance is not always better. Most users benefit most from mid-range protection with better dexterity.

🎯 Section 4: How to Choose the Right Anti-Cut Gloves

Assess the hazard

- Light prep work: A3–A5

- Metal or glass: A6–A9

- General DIY: A2–A5

Choose the right coating

- Nitrile for wet or oily conditions

- Polyurethane for precision

- Latex for flexibility

Get the right fit

- Snug but not restrictive

- Good finger movement

- Breathable for long wear

Consider durability

Steel mesh requires manual cleaning

HPPE and Kevlar are usually machine washable

Maintenance and Care (How to Make Them Last)

To ensure your gloves maintain their safety rating throughout their lifespan (typically 3–6 months), follow these care guidelines:

- Washing HPPE and Nitrile: Most HPPE gloves are machine washable. Use cold water and a mild detergent. Avoid high heat, as it can degrade the polyethylene fibers and shrink the glove, reducing its effectiveness.

- The “No Bleach” Rule for Kevlar: Never use bleach on Kevlar gloves. Chlorine bleach triggers a chemical reaction that permanently weakens the fibers, significantly lowering the cut protection level.

- Drying: Air drying is highly recommended. If you must use a dryer, use the “Tumble Dry Low” or “No Heat” setting.

- Inspection: Before every shift, check for “fuzzing” or broken fibers. If the inner core of the yarn is visible or the coating is peeling, the glove’s integrity is compromised and it should be replaced immediately.

Quick Care Guide: How to Wash Your Gloves

| Material | Washing Method | Detergent | Drying | What to Avoid |

| HPPE / Polyethylene | Machine Wash (Cold/Warm) | Mild Detergent | Air Dry (Preferred) or Tumble Dry Low | High Heat (fibers will melt/shrink) |

| Kevlar® (Aramid) | Machine Wash (Warm) | Mild Detergent | Tumble Dry Medium | Bleach (destroys cut protection) |

| Stainless Steel Mesh | Power Wash or Manual Scrub | Food-Grade Sanitizer / Soap | Air Dry | Ignoring debris trapped in links |

| Coated (Nitrile/PU) | Machine Wash (Cold) | Mild Detergent | Air Dry Only | Dryers (coating will crack or peel) |

Pro Tips:

- The Dishwasher Hack: For Stainless Steel mesh used in kitchens, many pros run them through a commercial dishwasher cycle to ensure every link is sanitized.

- Turning them Inside Out: When washing knit gloves (Kevlar/HPPE), turning them inside out helps remove the sweat and bacteria that build up against the skin.

- “Sun Warning”: Don’t leave Kevlar gloves on a windowsill. UV rays from the sun can actually weaken the fibers over time.

Common Mistakes When Choosing Anti-Cut Gloves

- Choosing maximum cut level when dexterity is required

- Ignoring grip coatings in wet or oily conditions

- Assuming cut-resistant gloves protect against heat

- Wearing gloves that are too loose or too tight

- Not replacing gloves once fibers are damaged

❓ Frequently Asked Questions

Are anti-cut gloves safe for needles?

Generally, no. Standard cut-resistant gloves are designed to stop a blade from slicing, but a sharp point (like a needle or thorn) can easily pass between the knit fibers. For needle protection, you need specialized puncture-resistant gear.

Are anti-cut gloves cut-proof?

No. They are cut-resistant, not cut-proof.

Can they be used for cooking?

Yes, as long as they are food-grade and labeled safe for food contact.

Kevlar or HPPE?

Kevlar handles heat better. HPPE offers better dexterity in cooler environments.

How long do they last?

Typically 3–6 months depending on use and care.

🏁 Final Thoughts

From food prep to industrial work, anti-cut gloves are one of the simplest ways to reduce hand injuries. Choosing the right glove means matching protection level, material, and task—not just buying the highest rating available.

This guide is your starting point. For deeper dives into specialized gloves, explore our detailed guides on chain gloves, woodworking gloves, and industrial hand protection.