What Is a Confined Space (and Why Air Safety Is Different)

What Is a Confined Space?

A confined space is an area that:

- Is large enough for a worker to enter and perform work

- Has limited or restricted means of entry or exit

- Is not designed for continuous occupancy

These spaces exist in many workplaces and are often part of normal operations.

Common examples include:

- Storage tanks and silos

- Pits, vaults, and sumps

- Manholes and sewer systems

- Pipelines and ducts

- Crawl spaces and utility enclosures

At first glance, many confined spaces do not appear dangerous. The risk comes from how air behaves once a worker enters.

For an overview of how confined spaces fit into broader air protection planning, see Confined Space Air Safety: Hazards, Monitoring, and Worker Protection.

Why Air Safety Is Different in Confined Spaces

In open areas, fresh air can dilute contaminants. In confined spaces, air movement is limited or nonexistent.

This creates several problems:

- Hazardous gases and vapors can accumulate

- Oxygen levels can drop without warning

- Air conditions can change rapidly during work

Because of this, safety practices that work in open environments may fail in confined spaces.

These risks build on the airborne contaminants found in many workplaces. If you need a baseline understanding, review Common Airborne Hazards in the Workplace.

How Gases Accumulate in Confined Spaces

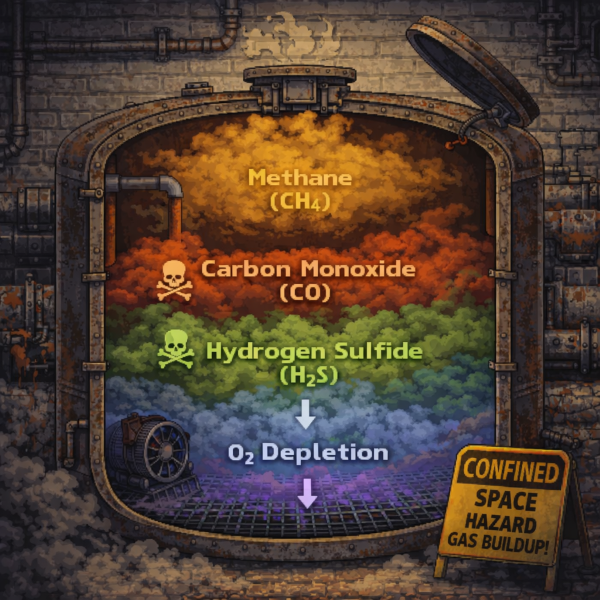

Airborne hazards behave differently depending on their weight and source.

- Heavier-than-air gases may settle near the floor or lowest points

- Lighter-than-air gases may collect near ceilings

- Vapors released during work may build up faster than they disperse

Without ventilation or monitoring, these hazards may go undetected until symptoms appear.

This is why confined spaces require air testing, not assumptions.

Why Standard Safety Assumptions Fail

One of the most dangerous assumptions is believing that “the air was safe last time.”

In confined spaces:

- Conditions can change between entries

- Chemical reactions may consume oxygen

- Nearby equipment may release gases unexpectedly

Another common assumption is that wearing a respirator alone makes entry safe. Respirators do not measure air quality and may not protect against all hazards present.

Understanding these limitations is essential before any confined space entry.

The Role of Air Monitoring

Because hazards are often invisible, air monitoring is a critical first step.

Monitoring helps determine:

- Whether oxygen levels are safe

- Whether hazardous gases are present

- Whether conditions are stable enough for entry

An overview of how these devices work and why they matter is covered in Gas Monitors and Air Detection Devices.

In confined spaces, monitoring drives decisions. It does not simply support protective equipment.

Confined Spaces Require a Different Mindset

Confined space safety is not just about protection. It is about judgment.

Before entry, workers and supervisors must ask:

- Is the air safe right now?

- Can conditions change during the task?

- What will alert us if they do?

This mindset separates confined space safety from routine workplace air protection.

Recommended Gas Monitors for Confined Space Entry

The following gas monitors are commonly used for confined space air testing and continuous monitoring when oxygen and multiple gas hazards may be present.