Ventilation and Airflow Control in Confined Spaces

Why Ventilation Matters in Confined Spaces

Ventilation is one of the most effective ways to reduce air hazards in confined spaces. While monitoring tells workers what is happening in the air, ventilation helps change those conditions.

Without adequate airflow, hazardous gases can build up, oxygen levels can drop, and air quality can shift rapidly during work. Relying on PPE alone in these environments increases risk.

For the overall framework that explains how ventilation fits into confined space safety, see Confined Space Air Safety: Hazards, Monitoring, and Worker Protection.

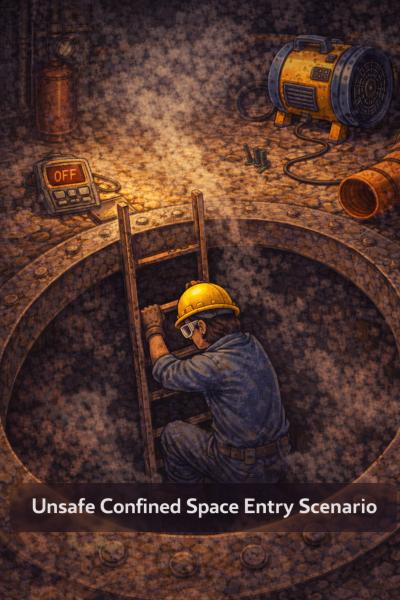

Why PPE Alone Is Not Enough

Respirators protect workers from certain airborne hazards, but they do not remove contaminants from the space.

In confined environments:

- Contaminants may exceed respirator limits

- Oxygen levels may drop below safe thresholds

- Conditions may change faster than workers can react

Ventilation addresses the source of the hazard by diluting or removing contaminants before they reach dangerous levels.

Understanding respirator capabilities and limits is explained in Types of Respirators and When to Use Them.

Natural Ventilation in Confined Spaces

Natural ventilation relies on existing openings to allow air movement.

This may include:

- Open hatches or access points

- Doors or vents that allow airflow

- Temperature or pressure differences

Natural ventilation can be effective in some situations, but it is often unpredictable and difficult to verify. Air monitoring should always confirm whether natural airflow is sufficient.

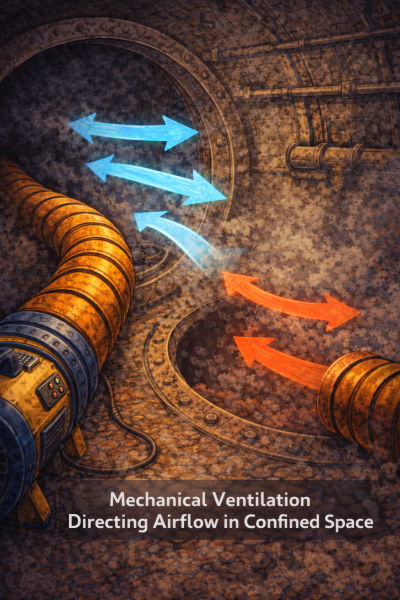

Mechanical Ventilation and Forced Airflow

Mechanical ventilation uses equipment to actively move air into or out of a confined space.

This approach:

- Provides more consistent airflow

- Can be directed to specific areas

- Helps control both oxygen levels and contaminants

Mechanical ventilation is often required when natural airflow is inadequate or when hazardous gases are present.

Monitoring should verify that ventilation is achieving the desired air quality.

Planning Airflow Before Entry

Ventilation planning should occur before workers enter the space.

Effective planning includes:

- Identifying contaminant sources

- Determining where fresh air should enter

- Directing exhaust away from workers

- Verifying airflow with air monitoring

Ventilation that is poorly planned may move contaminants toward workers instead of away from them.

Verifying Ventilation Effectiveness

Ventilation should never be assumed to work.

Air monitoring helps verify:

- Oxygen levels remain within safe limits

- Hazardous gas concentrations are controlled

- Conditions remain stable during work

If monitoring shows unsafe conditions, ventilation must be adjusted or entry stopped.

The relationship between monitoring and decision-making is explained further in Confined Space Gas Monitoring Requirements and Best Practices.

Ventilation Is Part of a Larger Air Safety Strategy

Ventilation works best when combined with:

- Continuous air monitoring

- Proper PPE selection

- Understanding respirator limitations

- Fit testing and training

Ventilation does not replace these controls. It strengthens them.

For a broader view of workplace air protection, see Respiratory & Air Safety in the Workplace: Risks, Protection, and Best Practices.

Recommended Products

Product examples are provided for informational purposes and do not replace site-specific hazard assessments, training, or regulatory requirements.