The Complete Guide to OSHA Safety Regulations in 2026

📚 Section 1: Introduction & The Core Mandate

Why Every Business Needs This Guide

OSHA penalties now exceed $16,500 per serious violation, and with increased inspection targeting, staying compliant is no longer optional—it’s essential. This guide breaks down what matters most, who it applies to, and how to stay ahead of enforcement trends in 2026.

The General Duty Clause

At the heart of OSHA is one simple principle: Employers must provide a workplace “free from recognized hazards that are causing or are likely to cause death or serious physical harm” (Section 5(a)(1)). It’s a catch-all standard that applies when no specific OSHA rule exists.

Who This Guide Is For

This guide primarily covers:

- Construction [29 CFR 1926]

- General Industry [29 CFR 1910]

These two sectors consistently see the highest number of violations and citations.

🔨 Section 2: The Big 4 — Most Cited Violations (The Preventable Risks)

A. Fall Protection – General Requirements (1926.501)

The Rule: Fall protection is required at 6 feet in construction and 4 feet in general industry.

The Fix: The ABCs of Fall Protection

- Anchorage: Must support at least 5,000 lbs per employee.

- Body Support: Use a full-body harness, not just a belt.

- Connectors: Include shock-absorbing lanyards, self-retracting lifelines, and anchor connectors.

Product Recommendations:

,

B. Hazard Communication (HazCom) (1910.1200)

The Rule: Employees have the “Right to Know” about chemical hazards. Every hazardous chemical must be evaluated and clearly communicated.

The Fix: 5 Key Components

- Written Program: A documented plan outlining compliance.

- Labels: GHS-aligned labels including pictograms, signal words (Danger/Warning), hazard & precautionary statements.

- Safety Data Sheets (SDSs): Must follow a 16-section format and be immediately accessible.

- Training: Required at hire and whenever a new hazard is introduced.

- Inventory: Maintain a complete list of hazardous chemicals on site.

C. Ladders (1926.1053 / 1910.23)

The Rule: Most violations stem from misuse or defective ladders.

The Fix:

- 4-to-1 Rule: For every 4 feet of height, the base should be 1 foot out.

- 3-Foot Extension: Ladder must extend 3 feet past the upper landing.

- Inspections: Tag and remove ladders with defects. Use “Danger: Do Not Use” labels.

D. Scaffolding (1926.451)

The Rule: Focuses on structural integrity and fall protection.

The Fix:

- Capacity: Must support 4x the intended load plus its own weight.

- Fall Protection: Required for heights over 10 feet; use guardrails or personal fall arrest systems.

- Competent Person: Must inspect scaffolding before each shift.

🌟 Section 3: What’s New in 2026 and Future Focus Areas

1. Expanded Injury & Illness Recordkeeping

Public access to workplace injury data is increasing. Employers with 100+ employees in high-risk industries must now electronically submit OSHA 300 and 301 data. Expect greater scrutiny and targeted inspections.

What to Do:

- Keep detailed records

- Regularly audit for near misses

- Train supervisors on incident reporting

2. Silica Exposure Enforcement

Respirable crystalline silica remains a top enforcement priority. Employers must:

- Create a written exposure control plan

- Use engineering controls (e.g., wet cutting, ventilation)

- Provide N95 or higher APF respiratory protection

3. Heat Illness Prevention (Proposed Rule)

Though not yet final, OSHA is prioritizing heat safety.

Best Practices:

- Provide access to shade, water, and rest breaks

- Monitor heat index levels

- Educate workers on heat stroke symptoms

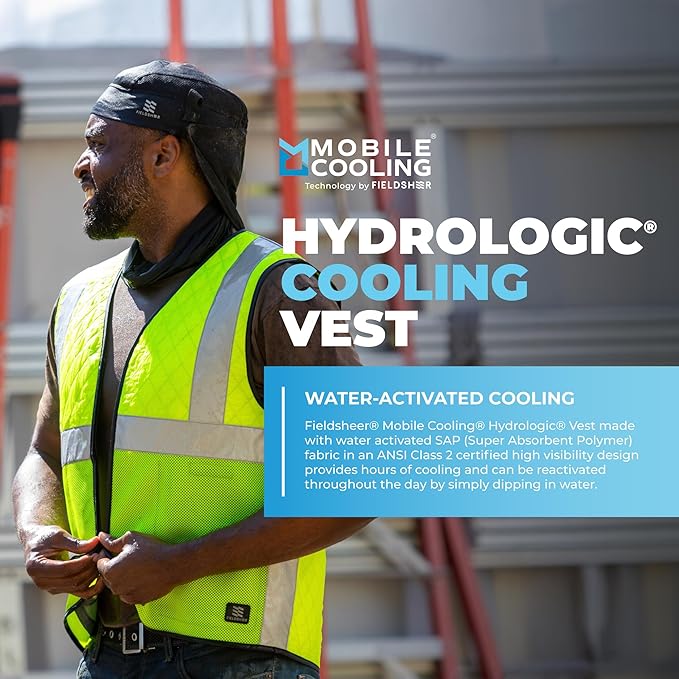

- Use cooling PPE (vests, bandanas)

Product Highlights:

✅ Section 4: The Compliance Checklist

Print-Friendly Tool: Available as a downloadable asset

📌 GENERAL COMPLIANCE

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| General Duty Clause is acknowledged and implemented | ||

| Emergency action plan is in place and reviewed | ||

| All workers are trained on basic OSHA rights and responsibilities | ||

| Safety programs are documented and accessible |

🔨 FALL PROTECTION (1926.501)

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| Fall protection used at 6+ ft in construction / 4+ ft in general industry | ||

| Full-body harnesses are used and inspected before each use | ||

| Anchors are rated for 5,000 lbs per user | ||

| Connectors (lanyards, lifelines) are present and in good condition | ||

| Training on fall protection systems is up-to-date |

🧪 HAZARD COMMUNICATION (1910.1200)

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| Written HazCom program is maintained | ||

| All hazardous chemicals have GHS-compliant labels | ||

| Safety Data Sheets (SDSs) are available and accessible to employees | ||

| HazCom training is provided at initial assignment and when new hazards are introduced | ||

| Chemical inventory list is current |

🪜 LADDERS (1926.1053 / 1910.23)

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| Ladders are inspected before use | ||

| Defective ladders are tagged and removed from service | ||

| Non-self-supporting ladders follow the 4-to-1 setup rule | ||

| Side rails extend 3 feet above the landing surface |

🛠️ SCAFFOLDING (1926.451)

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| Scaffold capacity meets or exceeds load requirements (4x intended load + own weight) | ||

| Fall protection in place for scaffolds over 10 feet | ||

| Guardrails or PFAS are used where required | ||

| Scaffold inspected by a competent person before each shift |

💨 SILICA SAFETY (1926.1153 / 1910.1053)

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| Written exposure control plan is in place | ||

| Engineering controls are used (ventilation, wet methods) | ||

| Appropriate respiratory protection provided (N95 or higher APF) | ||

| Silica training provided to exposed employees |

☀️ HEAT ILLNESS PREVENTION (Proposed)

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| Water, shade, and rest breaks available in hot conditions | ||

| Supervisors monitor heat index and symptoms of heat stress | ||

| Workers are trained to recognize heat-related illnesses | ||

| Cooling PPE (vests, bandanas) available as needed |

📊 RECORDKEEPING (1904)

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| OSHA 300, 300A, and 301 logs are current | ||

| Required injury/illness data submitted electronically | ||

| Logs are reviewed and posted annually (Feb–Apr) | ||

| Supervisors trained in proper injury reporting protocols |

🧰 PPE AND TRAINING

| Requirement | Status (✔/✘) | Notes |

|---|---|---|

| PPE is selected based on hazards and inspected regularly | ||

| Employees trained on correct PPE use | ||

| Hard hats, gloves, goggles, and footwear meet ANSI standards | ||

| Fit testing completed for required respirators |

PDF Downloads

🧾 Download the Free OSHA 2026 Checklist

Stay ahead of inspections and citations. This printable PDF covers the most cited violations, new 2026 updates, and daily/weekly safety checks.

👉 Click here to download

✅ Need a printable version? Download the OSHA 2026 Compliance Checklist PDF

❓ Section 5: Glossary & Next Steps

Glossary

- PFAS: Personal Fall Arrest System

- HazCom: Hazard Communication

- APF: Assigned Protection Factor

- LOTO: Lockout/Tagout

- SDS: Safety Data Sheet

Next Steps Looking for compliant, durable, and field-tested safety solutions? Century Safety Products has your back. From fall protection kits to heat stress gear and chemical handling PPE, we supply what your team needs to meet 2026 OSHA standards.