Confined Space Air Safety: Hazards, Monitoring, and Worker Protection

Who This Guide Is For

This guide is intended for safety managers, supervisors, and workers who may be required to enter or oversee confined space operations.

Confined spaces present some of the most dangerous air safety risks in the workplace. Unlike open work areas, these environments can trap hazardous gases, reduce oxygen levels, and change air conditions without warning.

Many serious injuries and fatalities occur not because workers ignored safety, but because normal assumptions about air quality no longer applied. In confined spaces, air hazards escalate quickly, and respiratory protection alone may not be enough.

This guide explains what makes confined spaces different, why air hazards are more severe, and how monitoring and ventilation decisions determine whether entry is safe at all.

For a broader overview of workplace air risks and protection strategies, see Respiratory & Air Safety in the Workplace: Risks, Protection, and Best Practices.

What Is a Confined Space?

A confined space is an area that:

- Is large enough for a worker to enter

- Has limited or restricted entry or exit

- Is not designed for continuous occupancy

Common examples include tanks, silos, pits, vaults, manholes, pipelines, crawl spaces, and utility enclosures.

What makes confined spaces especially dangerous is not just their shape or size, but how air behaves inside them. Limited airflow allows gases and vapors to accumulate and oxygen levels to change rapidly.

A more detailed breakdown of how confined spaces are defined and why air behaves differently is covered in What Is a Confined Space (and Why Air Safety Is Different).

Why Air Hazards Escalate in Confined Spaces

In open areas, hazardous air often disperses. In confined spaces, it does not.

Several factors increase risk:

- Poor or nonexistent natural ventilation

- Heavier-than-air gases settling at low points

- Lighter-than-air gases collecting near ceilings

- Chemical reactions that consume oxygen

- Equipment or processes that release vapors continuously

Many of these hazards are invisible and odorless. Workers may feel fine when they enter and become incapacitated minutes later.

These risks build on the airborne hazards found in many workplaces. If you need a foundation on common contaminants, review Common Airborne Hazards in the Workplace.

Why Detection Comes Before PPE

Respirators protect lungs, but they do not tell workers what is in the air.

In confined spaces, that distinction matters. A worker may be wearing the correct respirator and still be in immediate danger if:

- Oxygen levels drop below safe limits

- A gas exceeds the respirator’s protection range

- Air conditions change during the task

Gas monitors and air detection devices provide the information respirators cannot. They alert workers to unsafe conditions before symptoms appear and help determine whether entry should happen at all.

An overview of how these devices work and what they detect is explained in Gas Monitors and Air Detection Devices.

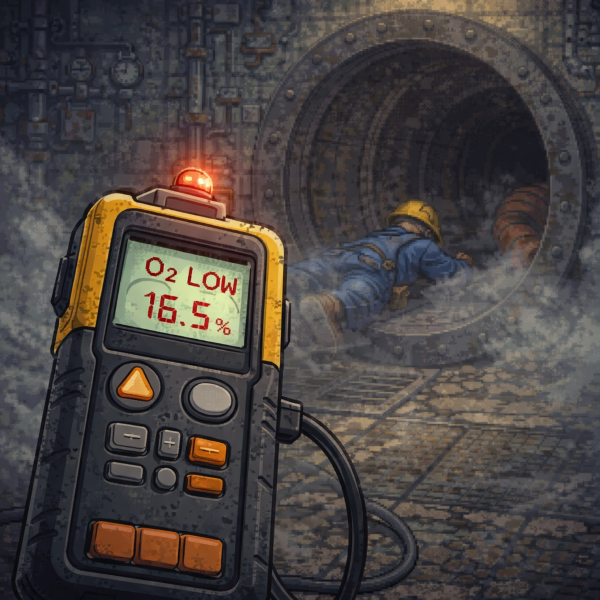

Oxygen Deficiency: A Critical Confined Space Risk

Oxygen-deficient environments are one of the leading causes of confined space fatalities.

Oxygen can be displaced by gases such as nitrogen, carbon dioxide, or argon. It can also be consumed by rusting, fermentation, combustion, or chemical reactions.

The danger is that oxygen loss provides little warning. Symptoms can include:

- Dizziness

- Confusion

- Loss of consciousness

- Death within minutes at very low levels

Most air-purifying respirators do not supply oxygen and offer no protection in oxygen-deficient spaces.

This risk and how it is detected is covered in detail in Oxygen Deficiency Hazards and How to Detect Them.

Monitoring Before and During Entry

Air testing should never be treated as a one-time step.

Best practice in confined spaces includes:

- Pre-entry testing to determine if entry is allowed

- Continuous monitoring while work is ongoing

- Alarms set to warn workers immediately when conditions change

Monitoring requirements vary by task, environment, and regulation, but the principle remains the same. Conditions can change faster than workers can react without alerts.

A deeper look at monitoring requirements, calibration, and alarm importance is provided in Confined Space Gas Monitoring Requirements and Best Practices.

Ventilation and Airflow Control

Ventilation is often the difference between a manageable hazard and a deadly one.

Confined space ventilation may involve:

- Natural ventilation when openings allow airflow

- Mechanical ventilation using blowers or fans

- Directed airflow to remove contaminants from breathing zones

Ventilation planning should occur before entry and always be verified through air monitoring. PPE should never replace proper airflow control.

How to plan and manage airflow safely is explained in Ventilation and Airflow Control in Confined Spaces.

When Entry Is Unsafe Even With Protection

Some confined spaces remain unsafe despite planning, monitoring, and PPE.

Examples include:

- Oxygen levels below respirator-safe thresholds

- Unknown or rapidly changing contaminants

- Equipment failures affecting ventilation or monitoring

- Alarm conditions that cannot be controlled

In these situations, the correct decision is to stop entry, not to add more protective equipment. Common errors that lead to serious incidents are discussed in Common Confined Space Entry Mistakes That Lead to Injury or Death.

Confined Space Air Safety as Part of a Larger Strategy

Confined space air safety does not replace respiratory protection programs. It builds on them.

Understanding respirator capabilities, limitations, and fit remains essential. However, confined spaces require additional decision-making based on real-time air conditions, not assumptions.

The following pages break down each element of confined space air safety in more detail, including equipment selection, monitoring practices, and common mistakes to avoid:

Together with gas monitoring and ventilation planning, these tools form a complete approach to protecting workers in high-risk air environments.nts.