Confined Space Gas Monitoring Requirements and Best Practices

Why Gas Monitoring Is Required in Confined Spaces

Confined spaces are unpredictable by nature. Air conditions that are safe one moment can become dangerous the next.

Because hazardous gases and oxygen deficiencies are often invisible, gas monitoring is not optional in confined space work. It is a critical control used to determine whether entry is allowed and whether work can continue safely.

Monitoring shifts air safety from assumption to evidence.

For the broader framework that explains why confined spaces require this level of control, see Confined Space Air Safety: Hazards, Monitoring, and Worker Protection.

When Gas Monitoring Is Required

Gas monitoring is typically required when:

- A space meets the definition of a confined space

- Oxygen levels may be affected

- Hazardous gases or vapors may be present

- The space has limited ventilation

- Work activities could change air conditions

Even spaces that are normally safe can become hazardous during cleaning, maintenance, or repair tasks.

Relying on past experience instead of current air testing is a common and dangerous mistake.

Pre-Entry Monitoring: Deciding If Entry Is Allowed

Before any worker enters a confined space, the air must be tested.

Pre-entry monitoring helps determine:

- Whether oxygen levels are within safe limits

- Whether toxic or flammable gases are present

- Whether ventilation is required before entry

Testing should be performed at multiple levels within the space since gases can stratify based on weight.

If unsafe conditions are detected, entry should be delayed until hazards are controlled or the task is reevaluated.

Continuous Monitoring During Entry

Air conditions in confined spaces can change quickly.

Continuous monitoring provides real-time information while work is in progress. This is critical when:

- Equipment is operating inside the space

- Chemicals are being used

- Ventilation effectiveness may change

- Leaks or releases are possible

Continuous monitoring allows workers to exit immediately if conditions become unsafe, rather than relying on symptoms or delayed observations.

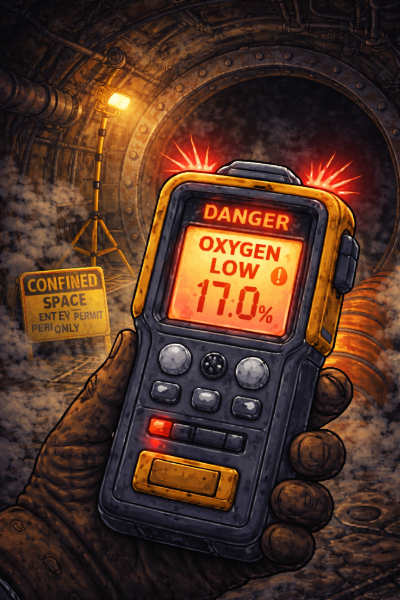

The Importance of Alarms

Gas monitors are only effective if their alarms are properly set and understood.

Audible, visual, or vibrating alarms alert workers when:

- Oxygen levels fall below safe thresholds

- Gas concentrations rise to dangerous levels

- Conditions approach regulatory limits

Ignoring alarms or assuming they are false is one of the most common causes of confined space incidents.

Alarms are warnings, not suggestions.

Calibration and Accuracy Matter

A gas monitor is only as reliable as its calibration.

Calibration ensures:

- Sensors respond accurately to known concentrations

- Alarm points trigger correctly

- Readings reflect real conditions

Using uncalibrated or poorly maintained monitors can create a false sense of security, which is often more dangerous than having no data at all.

Understanding how monitoring equipment fits into a larger air safety strategy is covered in Gas Monitors and Air Detection Devices.

Monitoring Does Not Replace Other Safety Controls

Gas monitoring is a decision-making tool, not a standalone solution.

Monitoring supports:

- Ventilation planning

- PPE selection

- Entry and exit decisions

It does not remove the need for:

- Proper ventilation

- Understanding respirator limitations

- Fit testing and training

Respirator fit and performance still matter and are addressed in Respirator Fit Testing.

Common Monitoring Mistakes in Confined Spaces

Serious incidents often involve one or more of the following errors:

- Testing only before entry and not during work

- Monitoring from outside the space only

- Ignoring alarm warnings

- Assuming one monitor covers all hazards

- Failing to maintain or calibrate equipment

Avoiding these mistakes starts with understanding the purpose of monitoring and using it consistently.

Recommended Gas Monitors for Confined Space Work

The following gas monitors are commonly used to support pre-entry testing and continuous monitoring in confined spaces where oxygen deficiency and multiple gas hazards may be present.

,

Product examples are provided for informational purposes and do not replace site-specific hazard assessments, training, or regulatory requirements.