Gas Monitors and Air Detection Devices: When Respirators Are Not Enough

Respirators protect workers from inhaling harmful substances, but they do not tell you what is in the air. In many workplaces, dangerous gases cannot be seen, smelled, or felt until it is too late.

Gas monitors and air detection devices exist to identify these hidden hazards before exposure occurs. They provide early warnings when air conditions become unsafe and help prevent serious injuries or fatalities.

For a broader overview of how air safety tools work together, see Respiratory & Air Safety in the Workplace: Risks, Protection, and Best Practices.

Why Gas Monitoring Is Critical in the Workplace

Some airborne hazards cannot be filtered or blocked by a respirator alone. Others can quickly overwhelm respiratory protection if workers are unaware of changing conditions.

Gas monitors help protect workers by:

- Detecting hazardous gases before symptoms appear

- Alerting workers to oxygen-deficient environments

- Identifying conditions where respirators may not provide protection

- Supporting emergency response planning and evacuation decisions

In environments where air conditions can change rapidly, detection is often the first and most important layer of protection.

Common Situations Where Gas Monitors Are Needed

Gas monitoring is essential in workplaces where hazardous gases may be present or oxygen levels may drop unexpectedly.

Common examples include:

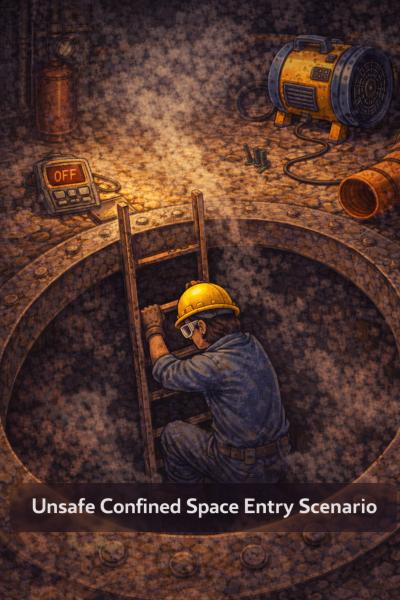

- Confined spaces such as tanks, pits, and vaults

- Manufacturing and chemical processing facilities

- Wastewater treatment plants

- Oil and gas operations

- Warehouses using fuel-powered equipment

These environments often contain risks that cannot be identified without monitoring equipment.

To understand the types of hazards that may be present, see Common Airborne Hazards in the Workplace:

Types of Gases Commonly Detected

Gas monitors are designed to detect specific gases or conditions that pose serious risks to workers.

Oxygen Deficiency

Low oxygen levels can cause dizziness, confusion, loss of consciousness, or death. Oxygen-deficient environments are especially dangerous because they provide little warning.

Toxic Gases

Gases such as carbon monoxide, hydrogen sulfide, and ammonia can be deadly even at low concentrations. These gases are often odorless or quickly overwhelm the senses.

Flammable Gases

Flammable gases can create explosion hazards if concentrations reach dangerous levels. Monitoring helps prevent ignition events and fires.

Types of Gas Monitors and Detection Devices

Different work environments require different types of monitoring equipment.

Portable Gas Monitors

These handheld or wearable devices allow workers to monitor air conditions in real time. They are commonly used in confined spaces or mobile work environments.

Fixed Gas Detection Systems

Fixed monitors are installed in specific locations to provide continuous monitoring. These systems are often tied into alarms or ventilation controls.

Single-Gas vs Multi-Gas Monitors

Some devices detect one specific gas, while others monitor multiple hazards at the same time. Multi-gas monitors are commonly used in environments with unknown or changing risks.

When Respirators Are Not Enough

Respirators are designed to filter or supply air, but they do not work in every situation.

Gas monitoring is critical when:

- Oxygen levels are too low for respirators to function safely

- The type of airborne hazard is unknown

- Gas concentrations may exceed respirator limits

- Conditions can change faster than workers can respond

In these situations, monitoring helps determine whether respiratory protection is appropriate or if evacuation is required.

For more information on selecting respiratory protection, see Types of Respirators and When to Use Them.

Gas Monitoring as Part of a Safety Program

Gas monitors are most effective when used as part of a complete air safety strategy.

That strategy may include:

- Hazard assessments

- Respiratory protection

- Fit testing and training

- Emergency response planning

- Equipment maintenance and calibration

Respirator fit testing ensures a respirator seals properly, but gas monitoring helps determine whether a respirator should be used at all. Together, they help reduce uncertainty and improve decision-making in hazardous environments.

Common Mistakes to Avoid

Some common issues with gas monitoring programs include:

- Relying on smell or symptoms instead of detection devices

- Using monitors that are not calibrated properly

- Ignoring alarms or disabling alerts

- Assuming a respirator provides protection in all conditions

Gas monitors provide critical information, but only if they are used correctly and taken seriously.

Final Thoughts

Gas monitors and air detection devices play a vital role in workplace safety. They identify hazards that cannot be seen and warn workers before conditions become life-threatening.

While respirators protect the lungs, gas monitors protect decision-making. Together, they help ensure workers are not exposed to dangers they cannot detect on their own.

Recommended Gas Monitors and Detection Devices

,