Respirator Filters Explained: What Really Protects You From Airborne Hazards

Choosing a respirator is only half of the equation. The filter or cartridge attached to that respirator is what actually determines what you are protected from. Using the wrong filter can leave workers exposed even when the respirator itself fits well.

This guide explains the main types of respirator filters, what they protect against, and how to choose the right one for workplace air hazards.

Why Respirator Filters Matter

Respirator filters are designed to remove specific contaminants from the air before they are inhaled. Some filters stop solid particles like dust, while others absorb chemical vapors or gases.

Understanding how filters fit into overall Respiratory & Air Safety in the Workplace: Risks, Protection, and Best Practices helps ensure protection is matched to real workplace risks, not assumptions.

A respirator without the correct filter is no better than wearing no protection at all.

Particulate Filters

Particulate filters are designed to trap solid particles suspended in the air.

What they protect against

- Dust

- Smoke

- Mists

- Non-oily and oily particulates

These filters are commonly used in construction, manufacturing, woodworking, and general industrial environments.

Common ratings

- N95 – Filters at least 95 percent of non-oily particles

- P100 – Filters at least 99.97 percent of particles, including oily aerosols

The higher the rating, the greater the level of protection, but breathing resistance may also increase.

Gas and Vapor Cartridges

Gas and vapor cartridges are designed to absorb or neutralize chemical contaminants rather than filter solid particles.

What they protect against

- Organic vapors

- Acid gases

- Ammonia

- Certain industrial chemicals

Each cartridge is formulated for specific substances. Using the wrong cartridge can result in breakthrough, where contaminants pass through unnoticed.

Combination Filters

Combination filters protect against both particulates and gases or vapors.

When to use them

- Environments with mixed hazards

- Areas where dust and chemical vapors are present

- Industrial cleaning or painting operations

These filters are common in workplaces where hazards are not limited to a single source.

For a better understanding of how different hazards develop, review Common Airborne Hazards in the Workplace, which helps identify when combination protection is needed.

Matching Filters to the Hazard

Choosing the correct filter starts with identifying the hazard.

Key questions to ask:

- Is the hazard a particle, a gas, or both?

- Is the chemical known or unknown?

- How concentrated is the exposure?

- How long will workers be exposed?

Choosing the correct filter also depends on the respirator being used. If you have not already selected one, review Types of Respirators and When to Use Them:

Filter selection should always align with the specific airborne risk present, not convenience or availability.

Filter Change-Out Schedules

Respirator filters do not last forever.

Signs a filter needs replacement include:

- Increased breathing resistance

- Odors detected while wearing the respirator

- Visible damage or contamination

- Manufacturer-recommended service life reached

Failing to replace filters on time can result in exposure even when the respirator appears to be working.

Compatibility and Fit Still Matter

Not all filters fit all respirators. Filters must be compatible with the respirator model being used.

In addition:

- Poor respirator fit can allow contaminated air to bypass the filter

- Improperly seated cartridges reduce effectiveness

- Facial hair can compromise the seal

This is why respirator fit testing plays a critical role in any respiratory protection program.

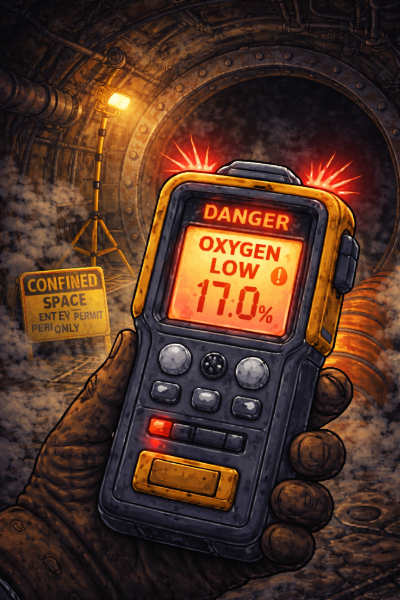

When Filters Are Not Enough

Filters and cartridges only work when oxygen levels are safe and hazards are known.

If the environment includes:

- Oxygen-deficient air

- Unknown chemical hazards

- High concentrations of toxic gases

Respirator filters alone may not provide adequate protection. In these cases, air monitoring and gas detection become essential safety tools.

Final Thoughts

Respirator filters are what make respiratory protection effective. Particulate filters, gas and vapor cartridges, and combination filters all serve specific purposes and must be selected carefully based on the hazard present.

Matching the right filter to the workplace risk improves safety, supports compliance, and reduces the chance of exposure over time.

In some environments, however, filters alone are not enough. When hazards are unknown, oxygen levels are unsafe, or toxic gases may be present, gas monitors and air detection devices are essential for identifying dangerous conditions before exposure occurs.

The next step in a complete protection plan is ensuring the respirator and filters fit the worker correctly, which is where many safety programs succeed or fail.

Recommended Respirator Filters and Cartridges

,