Types of Respirators and When to Use Them

Airborne hazards are present in many work environments, from construction sites and manufacturing floors to maintenance rooms and warehouses. Once those hazards are identified, the next step is choosing the right type of respirator to protect workers from inhaling harmful particles, vapors, or gases.

Not all respirators work the same way. Using the wrong type can create a false sense of safety and leave workers exposed. This guide breaks down the main types of respirators and explains when each one should be used.

For a complete overview of workplace respiratory protection, start with Respiratory & Air Safety in the Workplace: Risks, Protection, and Best Practices:

Why Choosing the Right Respirator Matters

Respirators are designed to reduce exposure to specific airborne hazards. Some protect against dust and particulates, while others are made to handle chemical vapors or toxic gases.

The level of protection needed depends on:

- The type of airborne hazard present

- The concentration of the hazard

- The duration of exposure

- Whether oxygen levels are safe

Understanding how respirators fit into overall Respiratory & Air Safety best practices helps ensure protection strategies match real workplace conditions:

Disposable Respirators

Disposable respirators are single-use masks designed to filter airborne particles.

When to use them

- Dust

- Non-toxic particulates

- Short-term exposure

- Low-risk environments

These are commonly used in construction, woodworking, and general maintenance.

Limitations

- Do not protect against gases or vapors

- Must fit properly to be effective

- Not suitable for high concentrations of hazards

Disposable respirators are often labeled with ratings such as N95 or P100, which indicate how well they filter particles.

Half-Mask Respirators

Half-mask respirators cover the nose and mouth and use replaceable filter cartridges.

When to use them

- Dust, fumes, and mists

- Some chemical vapors when paired with the correct cartridges

- Longer exposure periods

These respirators offer more protection than disposable options and are widely used in industrial and maintenance settings.

Key considerations

- Require proper fit testing

- Filters must be matched to the hazard

- Cartridges need regular replacement

Half-mask respirators strike a balance between comfort and protection when disposable masks are not enough.

Full-Face Respirators

Full-face respirators protect the nose, mouth, and eyes.

When to use them

- Chemical splashes or irritants

- High levels of airborne contaminants

- Situations where eye protection is critical

Because they seal around the entire face, these respirators provide a higher level of protection than half-mask models.

Benefits

- Eye and respiratory protection combined

- Better seal for hazardous environments

- Compatible with a wide range of filter cartridges

They are often used in chemical handling, painting, and industrial cleaning operations.

Powered Air-Purifying Respirators (PAPR)

Powered air-purifying respirators use a battery-powered blower to pull air through filters and deliver it to the user.

When to use them

- Long work shifts

- High-risk environments

- Situations where tight-fitting respirators are uncomfortable

Advantages

- Reduced breathing resistance

- Increased comfort

- Suitable for workers who cannot achieve a tight face seal with standard respirators

PAPRs are common in healthcare, manufacturing, and hazardous material response settings.

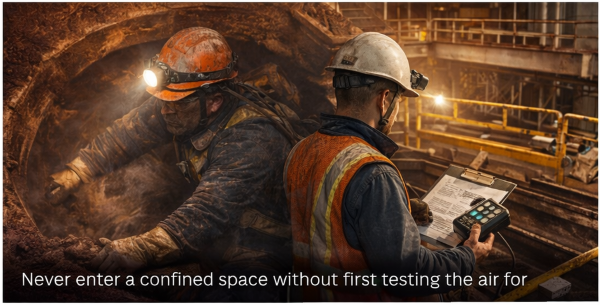

When Respirators Are Not Enough

Respirators rely on filtering contaminated air. They do not supply oxygen.

If an environment contains:

- Unknown airborne hazards

- Oxygen-deficient air

- High concentrations of toxic gases

Respirators alone may not be sufficient. In these situations, gas detection and air monitoring become critical for worker safety.

For a better understanding of how hazards develop, review Common Airborne Hazards in the Workplace to ensure respirator selection matches actual risks.

Choosing the Right Respirator for the Job

Selecting the right respirator involves more than picking a mask. It requires matching protection to the hazard, ensuring proper fit, and maintaining equipment correctly.

Important steps include:

- Identifying the specific airborne hazard

- Selecting the correct respirator type

- Using the right filters or cartridges

- Training workers on proper use and limitations

At this point in a safety plan, this is where many workplaces begin evaluating respirator options and supporting equipment.

FiFit and Maintenance Still Matter

Even the best respirator will fail if it does not fit properly or is not maintained.

Poor seals allow contaminated air to leak in, while old or clogged filters reduce protection. Improper storage can also damage equipment and shorten its usable life.

Because of this, respirator fit testing and routine inspection play a major role in effective respiratory protection programs, helping ensure each respirator provides the level of protection it was designed for.

The next step is understanding how filters and cartridges work and how to choose the correct one for specific hazards. This is covered in Respirator Filters Explained.

Final Thoughts

Respirators are a key part of protecting workers from airborne hazards, but only when the right type is used for the right situation. Disposable masks, half-mask respirators, full-face respirators, and PAPRs all serve different purposes.

Understanding these differences helps prevent exposure, supports compliance, and keeps safety programs practical and effective.

The next step is learning how respirator filters work and how to choose the correct one for specific hazards, which is where many safety programs gain or lose effectiveness.